Protect the heart of the refrigeration system

The compressor is the heart of the refrigeration system. The commonly used compressors we are talking about are composed of compressors and motors, which are divided into open compressors, semi-hermetic and full-hermetic. The compressor here refers to a semi-hermetic compressor. For easy understanding, the compressor is separated from the motor.

Compressor refers to a machine that can compress gas, compressing low-pressure gas into high-pressure gas, and the mechanical energy of the compressor is converted from electrical energy by the motor; that is, the motor converts electrical energy into mechanical energy of the compressor, and the compressor converts mechanical energy into Thermal energy, in the conversion process, energy conservation.

The function of the compressor is to compress the gas. The gap between the moving parts is very small. If it enters the liquid, it will cause great damage. The refrigerant liquid is not compressible, and the liquid will expand when it is heated, causing liquid hammer damage to the mechanical parts. This is why the compressor After the liquid returns, even if it is not damaged, the reason why the compressor is running loudly. Experienced system designers will strictly perfect the system to prevent refrigerant liquid from entering the compressor.

The compressor is a mechanical device with moving parts that need to be lubricated. The moving parts are subjected to strong impact and generate frictional heat. Therefore, the quality, viscosity and fluidity of the lubricating oil must be guaranteed. Since the lubricating oil contains refrigerant, it should be noted that the temperature of the lubricating oil.

For hermetic or semi-hermetic compressors, the lubrication of the compressor and the cooling of the motor have a great relationship with the running time of the system, especially for compressors that start frequently, if the time is short, the amount of lubricating oil reaching the friction surface is small, The motor coils are not sufficiently cooled. Long-term damage to the compressor and burnout of the motor will result.

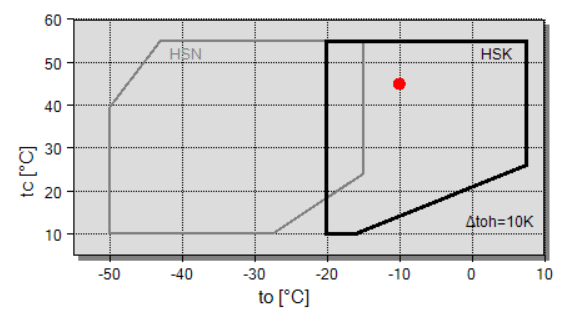

When the compressor is applied to different refrigerants, different pressure and density require different power, so the compressor has different operating ranges when it is applied to different refrigerants. If it exceeds this operating range, there is a risk of damage.In order to protect the compressor from running beyond the operating range, different refrigerants have different ranges, and set pressure control. When the system exceeds the pressure range, the compressor will be adjusted or protected to stop. Such as oil protection, discharge pressure protection, suction pressure protection, motor overcurrent protection, exhaust temperature protection, set according to the design operating range of the compressor.In order to protect the compressor from running beyond the operating range, different refrigerants have different ranges, and set pressure control. When the system exceeds the pressure range, the compressor will be adjusted or protected to stop. Such as oil protection, discharge pressure protection, suction pressure protection, motor overcurrent protection, exhaust temperature protection, set according to the design operating range of the compressor.

The compressor is a machine that forms high and low pressure to make the refrigerant flow. Only when there is a pressure difference, the refrigerant will flow to achieve cycle refrigeration. The factors affecting the efficiency of the compressor are the pressure difference, the internal leakage, that is, the clearance volume, and the pressure difference also affects the internal leakage. The suction pressure of the compressor is determined by the evaporation temperature, while the discharge pressure is affected by the temperature of the cooling medium and the exhaust resistance. Under the premise of ensuring the operating range of the compressor, reduce the exhaust pressure of the compressor as much as possible.

The compressor is a high-speed mechanical device, and the source of power is electricity. Ensuring the quality of the motor's power consumption, such as electricity and voltage, is crucial to the safe operation of the compressor motor; and the average gap between the rotor and the stator of the motor Very high, once damaged, the motor is easy to burn, and the cooling of the motor is carried out by the return air of the refrigerant, which is the reason why the compressor motor is not durable.