Fruit & vegetable cold storage

Refrigeration System: Employs a compression refrigeration unit consisting of a compressor, condenser, and evaporator, with two cooling methods: direct cooling (evaporator directly absorbs heat) and indirect cooling (air circulation for cooling). Structural Design: Insulation materials are used for walls and floors, and the exterior walls are painted in a light color to reduce heat absorption, creating a sealed, low-temperature environment.

Core Functions

Preservation and Extended Storage: Precise temperature control (-2~5℃ or 0~12℃) regulates the metabolic rate of fruits and vegetables,

reducing water evaporation and microbial growth.

Applicable Scenarios: Suitable for food factories, supermarkets, hospitals, laboratories, etc., for storing fruits, vegetables, meat, and pharmaceuticals.

Technical Features

Refrigeration System: Employs a compression refrigeration unit consisting of a compressor, condenser, and evaporator,

with two cooling methods: direct cooling (evaporator directly absorbs heat) and indirect cooling (air circulation cooling).

Structural Design: Insulated walls and floors, with light-colored exterior paint to reduce heat absorption, creating a sealed,

low-temperature environment.

Application Cases

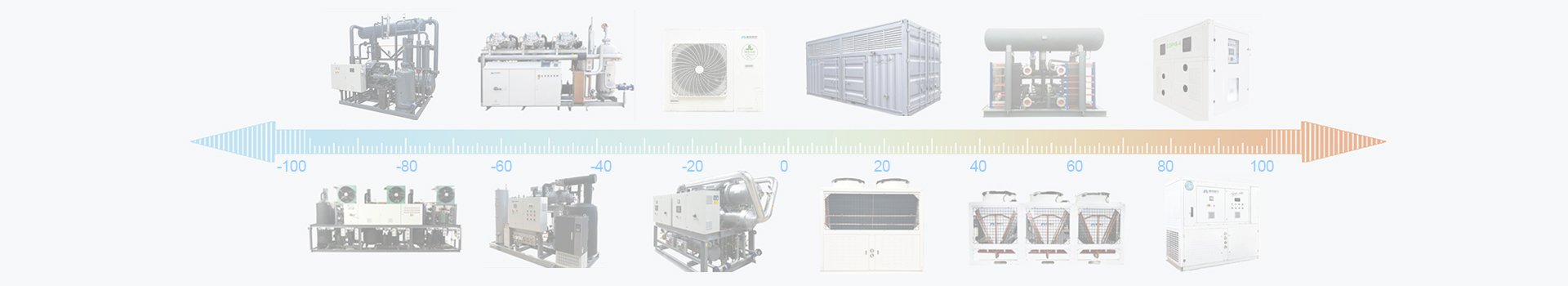

Customized Cold Storage: Such as a 1000-ton fruit and vegetable cold storage unit,

supporting temperature regulation from -40℃ to +20℃, suitable for storing fruits, vegetables, blood, and pharmaceuticals.

Mobile Cold Storage: Containerized refrigeration units, suitable for temporary or decentralized storage needs.

Maintenance Points

Regular Inspection: Check compressor operating status, oil level, and coolant circulation.

Storage Processing: Fruits and vegetables need to be pre-cooled and treated with preservatives to prevent spoilage caused

by sudden temperature changes.

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.